The Differential Gearbox

1. INTRODUCTION

2. FUNCTIONS OF DIFFERENTIAL GEARBOX

The main functions of a differential gearbox are as follows:-

1) Distributing torque evenly to both drive wheels:-

It means dividing the engine's rotational force (torque) equally

between the two drive wheels. This allows both wheels to receive the same

amount of power and provides better traction, stability, and control to the

vehicle. When a vehicle turns, the inside wheel has to travel a shorter

distance than the outside wheel, causing the inside wheel to rotate slower. The

differential gearbox allows for this difference in rotational speed by

distributing torque equally to both wheels, ensuring that the vehicle continues

to move forward smoothly and without any loss of traction.

2) Allowing wheels to rotate at different speeds during turns:-

When a vehicle makes a turn, the inside wheel has to travel a

shorter distance than the outside wheel. This difference in the distance

traveled by each wheel means that the inside wheel rotates at a slower speed

than the outside wheel.

Allowing wheels to rotate at different speeds during turns means

that the differential gearbox enables the wheels to rotate at different speeds,

compensating for the difference in their distances traveled. This allows the

vehicle to turn smoothly without any binding, slipping, or loss of traction.

3)Transfers power from the drive shaft to the axle shafts:-

Transfers power from the drive shaft to the axle shafts means that

the differential gearbox is responsible for transmitting the power generated by

the engine to the wheels that drive the vehicle.

In a typical drivetrain, the engine produces a torque which is

then transferred to the drive shaft. The differential gearbox is located

between the drive shaft and the axle shafts, and its main function is to

receive the torque from the drive shaft and distribute it to the two axle

shafts.

Each axle shaft is connected to a wheel and transfers the torque

to the wheel, providing the power needed to drive the vehicle. The differential

gearbox helps to evenly distribute the torque to both wheels, ensuring that the

vehicle moves forward smoothly and without any loss of power or traction.

4) Reducing wheel slippage on slippery surfaces:-

Reducing wheel slippage on slippery surfaces refers to the ability

of the differential gearbox to reduce the likelihood of the wheels losing

traction on surfaces with low friction, such as wet roads or ice.

When a vehicle is driving on a slippery surface, the wheels can

lose traction and start to slip. This can cause the vehicle to lose control and

skid. The differential gearbox can help to reduce wheel slippage by

distributing torque evenly to both drive wheels.

When the wheels receive equal amounts of torque, it helps to

maintain traction and stability, reducing the likelihood of slipping or losing

control on slippery surfaces. Additionally, some differential gearboxes, such

as limited-slip differentials, use special mechanisms to apply additional

torque to the wheel with the most traction, further reducing the risk of wheel

slippage.

3. NEED OF DIFFERENTIAL GEARBOX

The need for a differential gearbox arises from the requirement to

transmit the engine's power to the wheels while allowing each wheel to rotate

at different speeds. The main reasons for having a differential gearbox

include:

1. Improved traction: The differential allows both drive wheels to

receive equal amounts of torque, providing better traction, stability, and

control to the vehicle.

2. Smooth turning: When a vehicle turns, the inside wheel has to

travel a shorter distance than the outside wheel. The differential enables the

wheels to rotate at different speeds, compensating for the difference in their

distances traveled, allowing the vehicle to turn smoothly.

3. Reduced wheel slippage: The differential helps to reduce wheel

slippage by distributing torque evenly to both drive wheels, ensuring that the

vehicle moves forward smoothly on slippery surfaces.

4. Efficient power transfer: The differential receives the torque

from the drive shaft and distributes it to the two axle shafts, providing the

power needed to drive the vehicle efficiently.

Overall, the differential gearbox is an essential component in a

vehicle's drivetrain, allowing the engine's power to be transmitted to the

wheels while providing improved traction, stability, and control.

5. PRINCIPLE OF DIFFERENTIAL

The principle of a differential gearbox is based on the concept of

equal and opposite forces. The differential gearbox uses gears and bearings to

transfer torque from the drive shaft to the two axle shafts while allowing each

axle shaft to rotate at different speeds.

When a vehicle turns, the inside wheel has to travel a shorter

distance than the outside wheel. The differential gearbox allows the wheels to

rotate at different speeds by using gears and bearings to transfer torque from

the drive shaft to the two axle shafts.

The differential gearbox contains two bevel gears that are

arranged in a cross configuration, with the drive shaft attached to one gear

and the two axle shafts attached to the other two gears. The bevel gears mesh

with each other, allowing torque to be transferred from the drive shaft to the

axle shafts.

As the wheels turn, the bevel gears rotate, transmitting torque to

the axle shafts. The torque is then transferred from the axle shafts to the

wheels, providing the power needed to drive the vehicle. Because the inside

wheel has to travel a shorter distance than the outside wheel, the differential

gearbox allows each axle shaft to rotate at a different speed, compensating for

the difference in the distance traveled by each wheel and allowing the vehicle

to turn smoothly.

In summary, the principle of a differential gearbox is to use

gears and bearings to transfer torque from the drive shaft to the two axle

shafts, while allowing each axle shaft to rotate at a different speed, ensuring

that the vehicle can turn smoothly and efficiently.

6. DIFFERENTIAL GEARBOX DETAIL DIAGRAM

7. CONSTRUCTION

a) Bevel gears: Two bevel

gears are arranged in a cross configuration to mesh with each other, allowing

torque to be transferred from the drive shaft to the axle shafts.

c) Ring gear: The ring

gear is a large gear that surrounds the differential gears and receives torque

from the drive pinion.

d) Axle shafts: The axle

shafts are connected to the wheels and transfer torque from the differential

gears to the wheels.

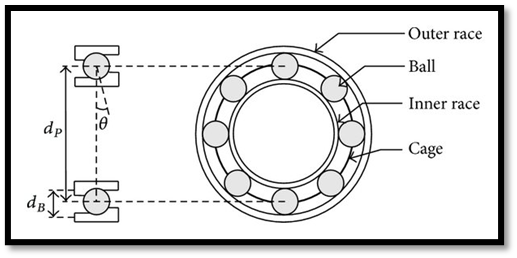

e) Bearings: Bearings are

used to support and reduce friction in the differential gears, allowing them to

rotate smoothly and efficiently.

f) Side Gears: The side gears are attached to the axle shafts and receive torque from the differential gears.

g) Spider gears: The spider

gears are the small gears that are located in the center of the differential

and mesh with the side gears, allowing the axle shafts to rotate at different

speeds.

The key parts of a differential gearbox, which allow each wheel to

rotate at a distinct speed, are, in summary, bevel gears, driving pinion, ring

gear, axle shafts, bearings, side gears, and spider gears. These parts work

together to deliver torque from the drive shaft to the wheels.

8. WORKING OF DIFFERENTIAL GEARBOX

The differential gearbox works by using gears and bearings to

transfer torque from the drive shaft to the two axle shafts while allowing each

axle shaft to rotate at different speeds. The main components of a differential

gearbox are the bevel gears, drive pinion, ring gear, axle shafts, bearings,

side gears, and spider gears.

1. The drive shaft is attached to the drive pinion, which is a small

gear that meshes with the ring gear. The ring gear is a large gear that

surrounds the differential gears and receives torque from the drive pinion.

2. The bevel gears are arranged in a cross configuration and mesh

with each other, allowing torque to be transferred from the drive shaft to the

axle shafts. The side gears are attached to the axle shafts and receive torque

from the differential gears.

3. The spider gears are the small gears located in the center of the

differential and mesh with the side gears, allowing the axle shafts to rotate

at different speeds. . The differential allows the wheels to rotate at

different speeds by using the spider gears to transfer torque to the axle

shafts.

4. The bearings are used to support and reduce friction in the

differential gears, allowing them to rotate smoothly and efficiently.

5. The differential gearbox continuously monitors the speed of each

wheel and adjusts the torque distribution accordingly, ensuring that both drive

wheels receive equal amounts of torque, providing improved traction, stability,

and control to the vehicle.

The differential gearbox

works by using gears and bearings to transfer torque from the drive shaft to

axle shafts, while allowing each axle shaft to rotate at different speeds,

ensuring that the vehicle can turn smoothly and efficiently.

9. TYPES OF DIFFERENTIAL GEARBOX

There are several types of differential gearboxes, each with its

unique features and applications:

1. Open differential: An

open differential distributes torque evenly to both wheels, allowing them to

rotate at different speeds. When one wheel loses traction, the open

differential diverts torque to the other wheel, reducing wheel slippage on

slippery surfaces.

2. A limited-slip differential (LSD): A limited-slip differential (LSD) is similar to an open

differential, but with a clutch mechanism that provides a limited amount of

torque to the wheel with less traction. This provides improved traction

compared to an open differential, especially on slippery surfaces.

3. Locking differential: A

locking differential uses a locking mechanism to force both wheels to rotate at

the same speed, providing maximum traction in difficult off-road conditions.

This type of differential is often used in four-wheel drive vehicles.

4. Torsen differential: A

Torsen differential uses worm gears to distribute torque between the wheels. It

automatically sends more torque to the wheel with better traction and less

torque to the wheel with less traction, providing improved traction and

handling.

5. Electronic differential: An electronic differential uses sensors and electronic controls

to monitor the speed of each wheel and adjust the torque distribution

accordingly. This type of differential can provide improved traction and

handling, especially in high-performance vehicles.

6. Epicyclic differential: An epicyclic differential uses planetary gears to transfer torque

between the wheels. This type of differential is often used in front-wheel

drive vehicles, where the differential is integrated into the transaxle

assembly.

In summary, there are several types of differential gearboxes,

including open differential, a limited-slip differential (LSD), locking

differential, Torsen differential, electronic differential, and epicyclic

differential, each with its unique features and applications.

10. SEVERAL ADVANTAGES OF A

VEHICLE WITH A DIFFERENTIAL GEARBOX

1. Improved Traction: By

distributing torque evenly to both drive wheels, the differential gearbox helps

to reduce wheel slippage on slippery surfaces, providing improved traction and

stability.

2. Better Handling: The

differential gearbox allows the wheels to rotate at different speeds during

turns, providing improved handling and maneuverability.

3. Increased Efficiency: The

differential gearbox allows the wheels to rotate at different speeds, reducing

friction and wear on the drive train components, and providing increased

efficiency and longer component life.

4. Enhanced Performance: The

differential gearbox provides improved traction, stability, and handling,

allowing the vehicle to perform better and respond more effectively to changes

in road conditions.

5. Increased Safety: The

differential gearbox helps to reduce wheel slippage on slippery surfaces,

providing improved traction and stability, which enhances the overall safety of

the vehicle.

6. Better Power Delivery: The differential gearbox transfers power from the drive shaft to

the axle shafts, providing more efficient power delivery to the wheels,

resulting in improved performance and fuel efficiency.

From this, we conclude that the differential gearbox provides several

advantages in a vehicle, including improved traction, better handling,

increased efficiency, enhanced performance, increased safety, and better power

delivery.

Institute and Group details are as follows:-

Bansilal Ramnath Agarwal Charitable Trust’s

Vishwakarma Institute of Technology

(An Autonomous Institute affiliated to Savitribai Phule Pune University formerly University of Pune)

Academic Year:- 2022 – 2023

Department:- Mechanical Engineering

Class:- SEDA

Batch:- 02

Group No.:- 04

Subject:- Analysis And Simulation Of Machines And Mechanisms

GROUP DETAILS:-

SR. NO. | NAME OF THE STUDENT | ROLL NO. | PRN NO. |

1 | Pooja Rajendra Lahare | 43 | 12220138 |

2 | Lavkesh Jagadish salunke | 44 | 12220211 |

3 | Varad Anand Lomte | 45 | 12220179 |

4 | Yash Balasaheb Mali | 46 | 12220205 |

5 | Nishiraj Nitin Mane | 47 | 12220010 |

6 | Kaustubh Vinod Palande | 54 | 12220132 |

Great👍

ReplyDeleteGreat information about differential gearbox..

ReplyDeleteNice Work 👍🏻

ReplyDeleteExcellent work guys great job.

ReplyDelete